1. Introduction to Machine Vision

In the realm of automation and technology, machine vision has emerged as a transformative force, reshaping industries by replacing manual inspection and analysis with automated systems that can “see” and interpret visual information. As manufacturers and organizations strive for higher productivity and better quality control, understanding machine vision becomes crucial. This article explores the definition, evolution, the mechanics of how machine vision works, its diverse applications, benefits, and future trends.

1.1 Definition of Machine Vision

Machine vision refers to the technology that enables machines to interpret visual information from the world around them. It combines cameras, computer hardware, and software to perform tasks such as inspection, guidance, and analysis in various applications. Unlike traditional imaging systems, machine vision systems are designed to automate specific tasks, making them invaluable in sectors like manufacturing, healthcare, and automation.

1.2 History and Evolution of Machine Vision

The roots of machine vision can be traced back to the mid-20th century when the first basic image processing methods were developed. Early systems were rudimentary, relying on simple pattern recognition algorithms to classify objects. As technology advanced, so did the complexity of these systems. In the 1980s and 1990s, advancements in computing power and the introduction of sophisticated algorithms led to the establishment of machine vision as a crucial component in industrial automation. Today, with the integration of artificial intelligence and machine learning, machine vision continues to evolve, becoming smarter and more capable of handling complex tasks.

1.3 Key Components of Machine Vision Systems

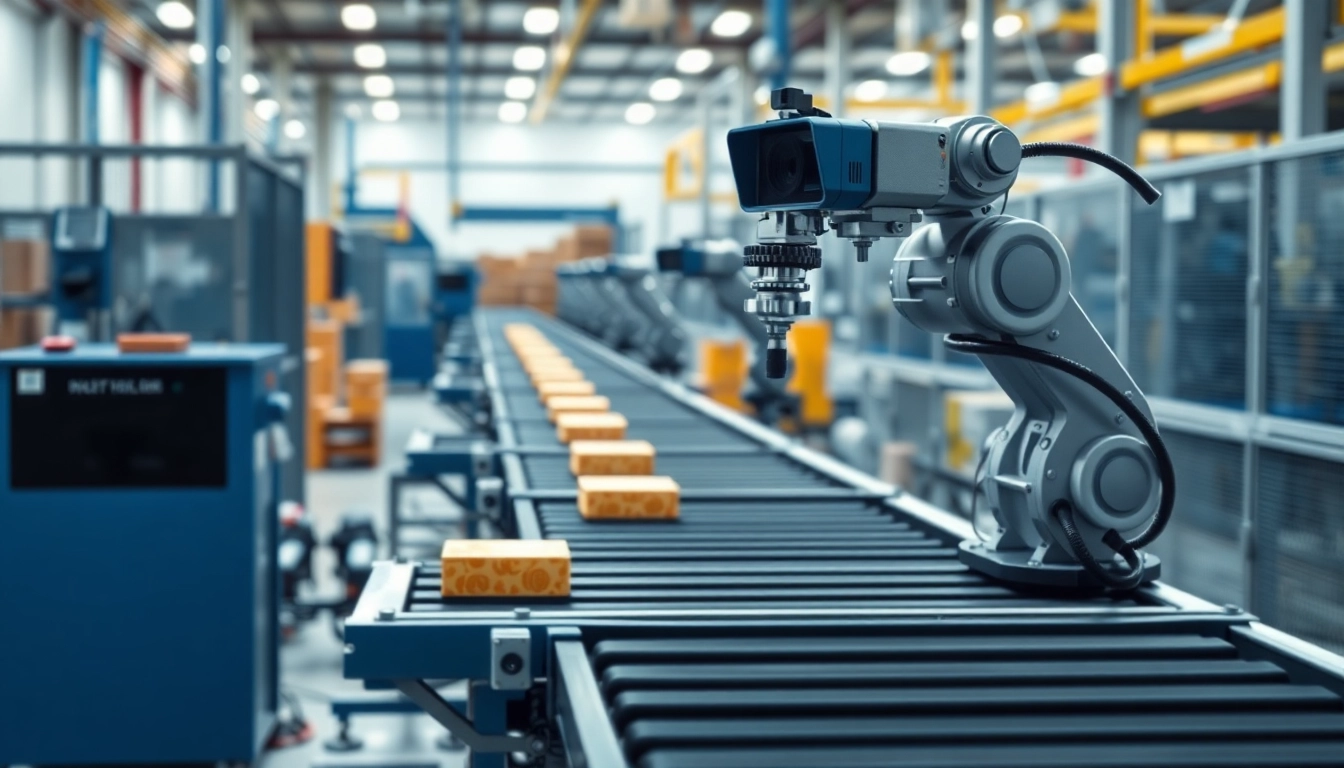

A typical machine vision system comprises several critical components that work in harmony:

- Cameras: The eye of the system that captures visual data.

- Illumination: It enhances image quality and contrasts for better analysis.

- Processing Hardware: This includes CPUs or GPUs that power image processing algorithms.

- Software Algorithms: These are essential for image processing, object detection, and analysis.

- Output Devices: Systems often include mechanisms to relay information to other systems, warning operators, or triggering actions.

2. How Machine Vision Works

2.1 Image Acquisition Techniques

The first step in a machine vision system is image acquisition. This involves capturing an image with a camera paired with specific lenses that focus on desired objects. There are various techniques for effective image acquisition, including:

- 2D Image Capture: This is the most common method, where standard cameras capture flat images of objects.

- 3D Image Acquisition: Systems employ techniques like laser triangulation or structured light to create a 3D representation of an object, providing depth information.

- Multispectral Imaging: This method uses sensors that capture data beyond visible light, extracting features not normally visible to the naked eye.

2.2 Image Processing Algorithms

Once the image is captured, processing algorithms come into play. These algorithms analyze the visual data by performing tasks like noise reduction, edge detection, and feature extraction. Common algorithms include:

- Thresholding: This separates objects from the background based on color or brightness.

- Template Matching: A technique that compares a captured image against predefined patterns to identify specific features.

- Deep Learning: Modern machine vision systems utilize convolutional neural networks (CNNs) to recognize intricate patterns, allowing for enhanced accuracy and object classification.

2.3 Real-Time Decision Making

The culmination of image acquisition and processing is real-time decision making. Machine vision systems can analyze visual data instantaneously, allowing them to make automated decisions. For example, in manufacturing, these systems can identify defective products on a conveyor belt, ensuring quality control before items reach consumers. This rapid reaction capability is critical in industries where time and precision are of the essence.

3. Applications of Machine Vision

3.1 Quality Control in Manufacturing

One of the most significant applications of machine vision is in quality control within manufacturing processes. Systems equipped with machine vision can continuously monitor production lines, identify defects, and ensure that products meet specified standards. For instance, in the electronics industry, machine vision systems can inspect intricate printed circuit boards (PCBs) for solder quality, component misalignment, and other potential defects.

3.2 Medical Imaging and Diagnostics

In the healthcare field, machine vision is profoundly beneficial. It enhances medical imaging technologies, providing physicians with precise diagnostic support. Application examples include:

- Pathology: Automated systems can analyze histological slides for cancer detection, significantly improving diagnostic accuracy.

- Radiology: Machine vision systems can support radiologists in identifying anomalies in X-rays or MRIs by analyzing patterns indicative of conditions.

3.3 Autonomous Vehicles and Robotics

Autonomous vehicles rely heavily on machine vision to navigate and interpret their surroundings. This technology assists in real-time processing of information gathered from cameras and sensors, allowing the vehicle to recognize road signs, detect obstacles, and make navigation decisions. Similarly, in robotics, machine vision empowers robots to perform complex tasks like box picking in warehouses and precise operations in surgical settings.

4. Advantages of Implementing Machine Vision

4.1 Efficiency and Productivity Improvements

The implementation of machine vision leads to substantial increases in efficiency and productivity. By automating visual inspection processes, organizations can significantly cut down on the time and labor required for these tasks. Moreover, machine vision systems can operate continuously without fatigue, ensuring a consistently high output level.

4.2 Enhanced Accuracy and Consistency

One of the critical advantages of machine vision systems is their ability to maintain high accuracy and consistency. Compared to human inspection, which can be prone to error due to fatigue or distraction, machine vision systems provide reliable analysis and decision-making based on predefined criteria. This consistency is vital in industries such as pharmaceuticals and aerospace, where precision is non-negotiable.

4.3 Cost-Effectiveness Over Time

While there may be initial investments associated with deploying machine vision systems, the long-term cost-effectiveness is undeniable. By reducing labor costs, minimizing waste due to defects, and increasing throughput, machine vision can provide significant financial savings over time.

5. Future Trends in Machine Vision

5.1 AI and Machine Learning Integration

The integration of artificial intelligence (AI) and machine learning into machine vision systems marks a significant trend for the future. AI enhances the systems’ ability to learn from data patterns, significantly improving object recognition capabilities. This allows machine vision to adapt to new types of inspection tasks and environmental challenges without needing extensive reprogramming.

5.2 Developments in Imaging Technology

Continuous advancements in imaging technology, including higher resolution cameras and improved sensors, will further propel machine vision applications. These developments will allow for finer detail analysis and better performance under various lighting conditions, thereby expanding the potential domains where machine vision can be effectively utilized.

5.3 Expanding Use Cases Across Industries

The versatility of machine vision means that its applications will continue to expand across diverse industries. From agriculture, where drone-based vision systems can monitor crop health, to retail, where facial recognition can enhance customer experiences, the future of machine vision is broad and filled with possibilities. As industries increasingly adopt automation, machine vision will play a pivotal role in enabling the next wave of innovation.