Understanding the Oxy Gas Welding Kit

What is an Oxy Gas Welding Kit?

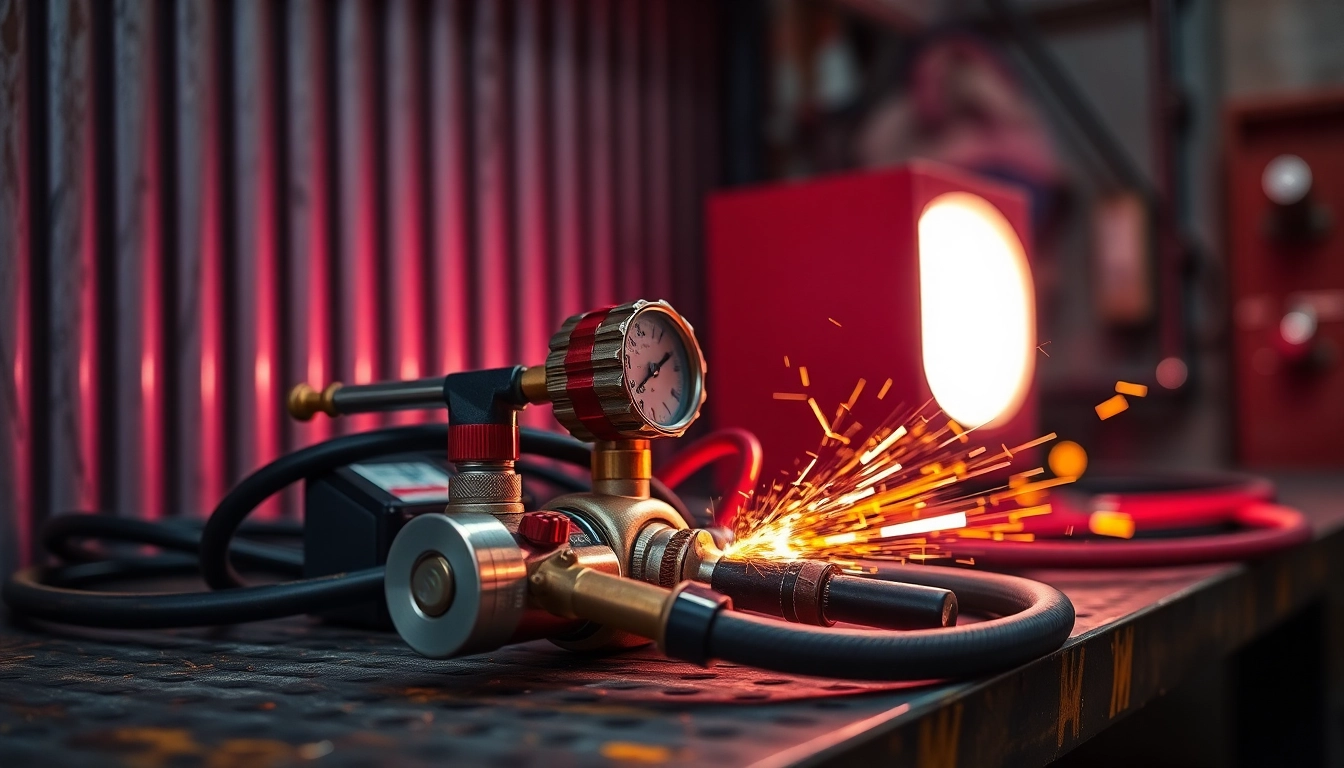

An oxy gas welding kit is a specialized assembly of tools designed for the process of oxy-fuel welding, commonly using a combination of oxygen and acetylene. This type of welding process relies on the combustion of acetylene in the presence of oxygen to create a high-temperature flame that can melt and fuse metal surfaces. Oxy gas welding kits are versatile tools used in various industries, including automotive, metalworking, and construction, due to their portability and effectiveness in both cutting and welding applications. Oxy gas welding kits typically include essential components such as torches, regulators, hoses, and fuel tanks.

Components of Oxy Gas Welding Kits

An effective oxy gas welding kit consists of several key components, each playing a critical role in the welding process. Here’s a breakdown of the main components:

- Oxygen Cylinder: Contains pressurized oxygen to support the combustion of acetylene, producing a high-temperature flame.

- Acetylene Cylinder: Contains acetylene gas, the primary fuel for generating heat in the welding process.

- Regulators: Control the gases flowing from the cylinders to the torch, ensuring the ideal mixture for welding.

- Welding Torch: The tool through which the gas mixture is ignited to create the flame needed for welding.

- Hoses: Flexible tubes that transport the gases from the cylinders to the regulators and then to the torch.

- Welding Goggles and Protective Gear: Essential for protecting the welder’s eyes and skin from intense light and heat.

- Welding Rods (optional): Sometimes included in kits for additional material during the welding process.

Applications of Oxy Gas Welding

Oxy gas welding finds applications across various industries due to its effectiveness and versatility. Key usage areas include:

- Metal Fabrication: Used extensively to join different metal parts, making it crucial in fabricating metal structures, frames, and machinery.

- Automotive Repair: Commonly used in the automotive industry for repairs and modifications of metal components.

- Artistic Metalworking: Artists use oxy gas welding techniques to create sculptures and intricate designs from metal.

- HVAC Industry: Essential for installing and maintaining heating, ventilation, and air conditioning systems by joining metal ductwork.

- Pipe Welding: Used in plumbing and construction to fuse pipes, ensuring watertight and durable connections.

Choosing the Right Oxy Gas Welding Kit for Your Needs

Factors to Consider When Selecting a Kit

Choosing the right oxy gas welding kit requires careful consideration of several factors to ensure it suits your specific needs. Here are essential aspects to keep in mind:

- Purpose: Determine what types of projects you will tackle. Heavy-duty kits are necessary for industrial applications, while lighter kits suffice for hobbyist work.

- Gas Cylinder Size: Select the size of the oxygen and acetylene cylinders based on your operational needs. Larger cylinders provide longer working times.

- Regulator Type: Ensure the kit includes quality regulators that can maintain consistent pressure and flow rates for optimal performance.

- Portability: If mobility is a concern, choose a kit that includes lightweight components and a sturdy carrying case.

- Brand Reputation: Opt for products from well-known brands recognized for their quality and reliability in the welding industry.

- Cost: Compare prices across various suppliers, but remember that cheaper options may compromise on quality.

Top Brands in Oxy Gas Welding

When selecting an oxy gas welding kit, it is vital to consider reputable brands that have a history of producing quality equipment. Some top brands in the market include:

- Victor: A leading manufacturer known for its reliable and high-performance welding torches and kits.

- Harris: Offers a range of oxy-fuel equipment that is durable and effective for numerous welding applications.

- Lincoln Electric: Renowned for its innovative welding technologies and comprehensive kits aimed at both newbies and experienced welders.

- ESAB: Provides a diverse range of oxy gas welding products to cater to various industrial needs.

- Unimig: Known for affordable and functional welding solutions, particularly in the Australian market.

Comparing Prices and Features

Prices of oxy gas welding kits vary widely, influenced by factors such as brand, included components, and overall quality. Here’s how to approach price comparisons:

- Feature Comparison: Make a list of essential features you need and compare the offerings of different models accordingly.

- Online Reviews: Browse reviews and customer feedback to identify the strengths and weaknesses of specific kits from various vendors.

- Local Suppliers vs. Online Retailers: Compare prices from local welding supply stores with those from online retailers to find the best deal.

- Warranty and Support: Consider the warranty offered by the manufacturer. Kits with longer warranty periods often indicate better quality.

Safety Precautions When Using an Oxy Gas Welding Kit

Essential Safety Gear for Operators

Safety is paramount in oxy gas welding due to the high risks associated with working with pressurized gases and open flames. Essential safety gear includes:

- Welding Goggles: Protect your eyes from intense light and harmful radiation produced during welding.

- Flame-Resistant Clothing: Wear protective clothing that reduces the risk of burns and fire injuries while working.

- Gloves: Use heat-resistant gloves to protect your hands from burns and abrasions.

- Respirator: Consider a respirator if working in poorly ventilated areas to avoid inhaling harmful fumes.

- Ear Protection: Use earplugs or earmuffs if working near loud machinery or in industrial settings.

Common Hazards and How to Avoid Them

Understanding the common hazards in oxy gas welding and implementing preventive measures is crucial for safety. Some key hazards include:

- Gas Leaks: Regularly check hoses, fittings, and connections for leaks. Use soapy water to identify leaks and never operate a leaking system.

- Fires and Explosions: Keep flammable materials away from the work area and always have a fire extinguisher nearby.

- Burns: Maintain a safe distance from the flame and ensure that your workspace is clear of debris and flammable materials.

- Inhalation of Harmful Fumes: Ensure adequate ventilation in the working area to disperse harmful gases produced during welding.

Emergency Procedures

In the event of an emergency during gas welding operations, it is vital to have established procedures in place:

- Emergency Shutdown: Know how to quickly shut off all gas supplies in case of leaks or fires.

- First Aid Training: Ensure at least one person is trained in first aid within the group to address burns or injuries on-site.

- Emergency Contacts: Keep a list of emergency contact numbers, including fire services and medical assistance, easily accessible.

- Regular Drills: Conduct training drills to prepare all personnel for responding to emergencies effectively.

Tips for Optimal Performance of Your Oxy Gas Welding Kit

Regular Maintenance Practices

To ensure efficiency and longevity of your oxy gas welding kit, routine maintenance is essential. Here are some best practices:

- Inspection: Regularly inspect hoses and regulators for signs of wear or damage, replacing them as necessary.

- Cleaning: Keep the welding torch and nozzles clean from impurities for efficient gas flow and performance.

- Storage: Store gas cylinders securely in an upright position away from heat sources and in well-ventilated areas.

- Calibration: Periodically calibrate regulators to maintain accurate pressure readings for optimal performance.

Maximizing Efficiency During Use

Maximizing the performance of your oxy gas welding kit involves techniques that can lead to better results:

- Gas Adjustment: Adjust the gas flow rates correctly before starting to ensure a neutral flame for most welding applications.

- Welding Techniques: Familiarize yourself with different welding techniques for various materials to achieve the best welds.

- Preheating: For thicker materials, consider preheating the area to be welded to enhance the welding outcome.

- Practice: Regular practice is essential in developing skills to handle the torch and achieving precise welds.

Common Issues and Troubleshooting

Having the knowledge to address common issues that arise during welding can save time and resources:

- Flame Fluctuations: This may occur due to inconsistent gas flow; check regulators and hoses for blockages or leaks.

- Weld Quality Issues: Issues like porosity or weak welds can often be traced back to inadequate gas mixtures; ensure settings are correct.

- Overheating: If materials are becoming too warped, manage your torch distance and travel speed to prevent overheating.

Reviews and Recommendations for Oxy Gas Welding Kits

Comparative Reviews of Popular Models

Based on extensive research and customer feedback, here are some reviews of popular oxy gas welding kits:

- Victor G150: This model is praised for its robust design and excellent gas flow control. Ideal for both professional and amateur welders.

- Harris 20: Known for affordability and reliability, this kit is suitable for light fabrications and repairs.

- Lincoln Electric Handy MIG: This versatile kit offers both MIG and oxy-fuel capabilities, making it a valuable choice for diverse welding tasks.

Customer Recommendations and Insights

Collecting insights from users of oxy gas welding kits can highlight real-world performance:

- Many users recommend investing in quality regulators due to their impact on overall torch performance.

- Customers emphasize the importance of proper training, noting that safety practices significantly affect their welding experience.

Conclusion: Finding the Best Oxy Gas Welding Kit

Choosing the right oxy gas welding kit requires understanding your specific needs, considering the components, and adhering to safety protocols. As you explore various options, remember to focus on durability, functionality, and the quality of the included parts. Additionally, adopting good maintenance practices and safety awareness will enhance both performance and longevity. The right kit not only facilitates excellent welds but also supports safe and efficient working conditions, allowing welders to produce exceptional results efficiently.