Understanding Oxy Gas Welding Kits

Welding is an essential technique utilized in various industries and crafts. Among the different welding methods available, oxy gas welding kits stand out for their versatility and effectiveness. In this comprehensive guide, we will delve into the intricacies of oxy gas welding kits, exploring their components, benefits, applications, and maintenance practices.

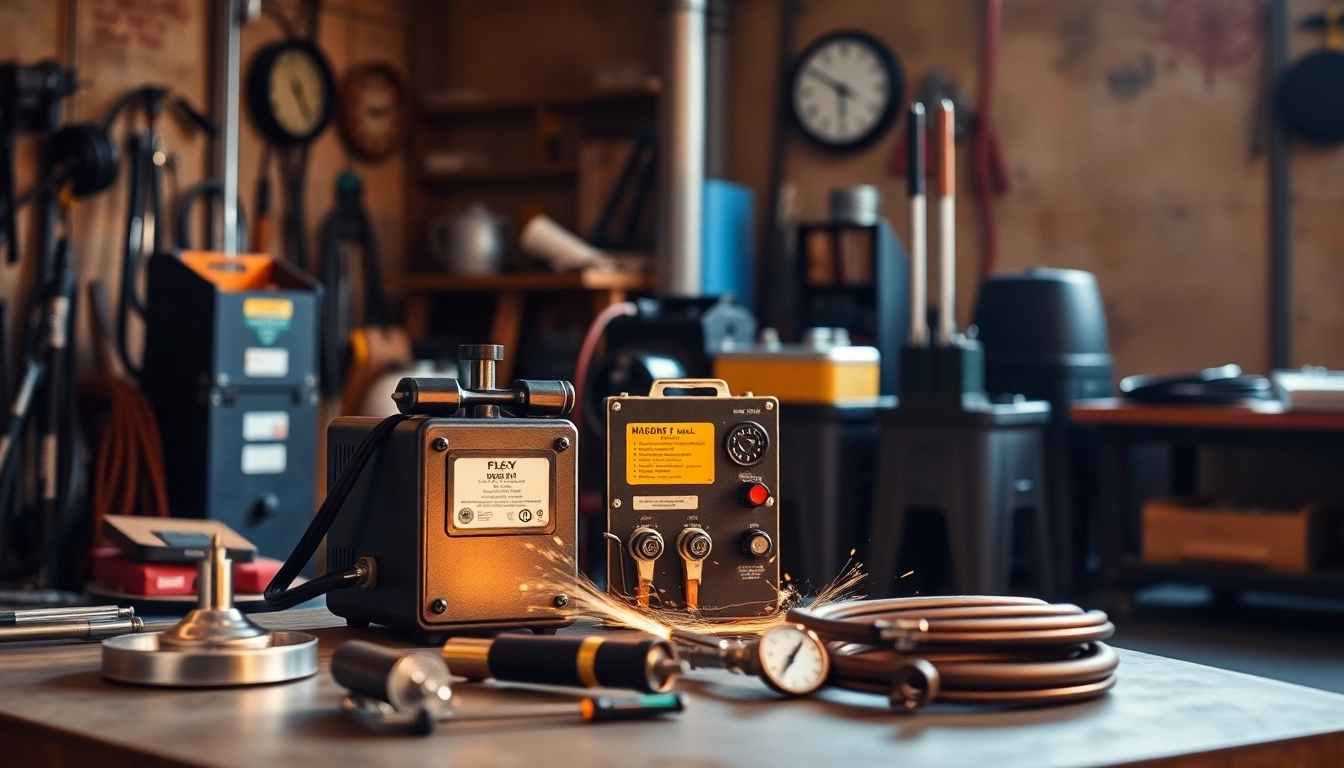

What is an Oxy Gas Welding Kit?

An oxy gas welding kit, often referred to as oxy-acetylene or oxy-fuel welding kit, is a system designed for cutting and welding metals using a flame produced by a mixture of oxygen and a fuel gas, typically acetylene. This method of welding is characterized by its ability to generate high temperatures, surpassing 3,200 degrees Celsius (5,792 degrees Fahrenheit), making it suitable for jointing a wide range of materials including steel, aluminum, and copper.

Key Components of Oxy Gas Welding Kits

An oxy gas welding kit typically consists of the following key components:

- Gas Cylinders: Tanks for oxygen and acetylene, usually made of high-strength steel to withstand high pressure.

- Regulators: Devices that control the flow and pressure of gas from the cylinders to the torch.

- Welding Torch: The handheld device where the welding process occurs. It mixes oxygen with acetylene to create the flame.

- Hoses: Flexible tubes that transport gases from cylinders to the torch; they are color-coded for safety, with red typically indicating acetylene and green for oxygen.

- Cutting Attachments: Tools that enable the user to perform precise cutting tasks along with welding.

- Safety Gear: Equipment such as goggles, gloves, and aprons designed to protect the welder from sparks and heat.

Benefits of Using Oxy Gas Welding

The use of oxy gas welding kits comes with various benefits:

- Versatility: They can be used for welding, cutting, brazing, and heating, making them suitable for a wide range of applications.

- Portability: Most kits are designed for mobility, allowing for use in various locations, whether in a workshop or onsite.

- Cost-Effectiveness: Typically, oxy gas welding can be less expensive compared to other methods, particularly for small-scale tasks.

- Customization: The flame can be adjusted easily for different operations, allowing for fine control over the temperature and the resulting weld.

Features to Look for in an Oxy Gas Welding Kit

Quality and Durability

When selecting an oxy gas welding kit, assessing the quality and durability of the components is essential. Look for kits that meet industry standards and certifications, indicating the materials used can withstand the rigors of regular use. High-quality regulators and hoses are vital for safe and effective operation, ensuring a steady flow of gas and minimizing the risk of leaks.

Accessories Included in the Kit

Consider which accessories are included in the kit. A comprehensive kit should provide all necessary tools for a variety of welding and cutting tasks. Essential attachments such as cutting torches, nozzles for different metal thicknesses, and safety gear are critical for usability and ensuring safety during operation.

Safety Features and Standards

Safety should always be a priority in welding. Ensure that the oxy gas welding kit includes features such as flame arrestors, flashback arrestors, and pressure relief valves. Understanding and adhering to safety standards, such as those established by the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI), play a critical role in selecting a safe welding kit.

Common Applications for Oxy Gas Welding Kits

Fabrication and Repairs

Oxy gas welding is widely used in fabrication shops for repairing metal parts, welding pipes, and connecting structural components. Its ability to provide precise heat makes it ideal for detailed work, where stronger and more reliable welds are required.

Use in Automotive and Metalworking

In the automotive sector, oxy gas welding kits are often used to repair and maintain vehicles. They are beneficial for cutting out old, damaged sections of metal and welding in new panels. Similarly, in metalworking, these kits allow craftsmen to manipulate metal for various artistic and functional purposes.

Hobbies and Crafts

For hobbyists and artisans, oxy gas welding can be an excellent addition to their toolset. Whether creating sculptures, jewelry, or custom furniture, the ability to cut and weld metal offers endless creative possibilities.

Comparing Top Oxy Gas Welding Kits on the Market

Price Ranges and Budget Options

Oxy gas welding kits vary significantly in price, ranging from budget-friendly options to professional-grade setups. Consumers should evaluate what they need for specific tasks to find a suitable kit that balances quality with cost. Popular budget kits are generally adequate for hobbyists, while professionals may require more robust systems that feature advanced controls and enhanced safety measures.

Consumer Ratings and Reviews

Before purchasing an oxy gas welding kit, it’s beneficial to consult consumer ratings and reviews. This feedback provides insights into user experiences, reliability, and overall satisfaction with the kit. Products with consistently high ratings might be more dependable and serve the user’s needs effectively.

Brand Reputation and Warranty Information

Brand reputation plays a crucial role in selecting a welding kit. Established brands often have better track records and offer comprehensive customer support. Additionally, warranty information should be reviewed; a robust warranty can provide reassurance regarding the longevity and reliability of your investment.

Maintaining Your Oxy Gas Welding Kit

Routine Cleaning and Care Tips

To ensure the longevity and effectiveness of your oxy gas welding kit, regular maintenance is essential. Clean the torch tips, hoses, and regulators to prevent blockages and corrosion. Check for gas leaks regularly using soapy water; if bubbles form, it indicates a leak. Replace worn-out hoses and nozzles promptly to maintain safety during welding operations.

Storage and Safety Practices

Proper storage of your oxy gas welding kit is vital for safety and longevity. Store gas cylinders upright in a cool, well-ventilated area away from flammable materials. Ensure that hoses and torches are coiled properly to prevent kinks and wear. Always have a fire extinguisher nearby when working with welders to handle potential accidents.

Signs of Wear and When to Replace

Be vigilant for signs of wear in your equipment, including frayed hoses, rust on tanks, or overly discolored regulator gauges. If you notice any of these issues, consider replacing the affected components or the entire kit. Timely replacement is critical in upholding safety and performance standards during welding operations.